MCD 2E ENGINE: Principle of work - WEB TCS English

Main menu:

WHAT WE DO > PROJECTS > PROJECT SAMPLES > MCD 2E DOUBLE EXPANSION ENGINE

PROJECT SAMPLES

MCD 2E Double Expansion Engine

Principle of work

The MCD 2E Double Expansion Engine (also known as “Ortuño engine”) is a reciprocating, four different stroke, double row, six cylinder, radial piston engine developed by Dr. Eng. José Ortuño.

Figure 1 shows the curve described by the crank-pin axis and its four different dead centers that lead to four different piston strokes.

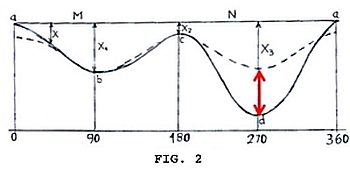

Figure 2 shows the piston distance X to the cylinder head during the four cycle strokes.

Specific fuel

consumption

20% lower

Lower exhaust

noise

Simple exhaust

system

Main Characteristics

The expansion stroke X3 is two times longer than the admision stroke X1 and the increment of useful energy obtained is aproximately 20% with respect to an equal standard piston engine.

Due to the final expansion low pressure, the noise level is also reduced in relation to a conventional engine.

Other important feature is that burnt gases are totally scanvenged from the cylinder by the piston in this process, points “a” and “a´” in Fig. 2. This means that the next cycle gas temperature is lower and the compression ratio can be higher.

Combustion gases are less polluting and easier to treat, making even unnecessary the incorporation of a conventional catalyst.

The output shaft is ½ gear reducted and also actuates as camshaft for the valve distribution.

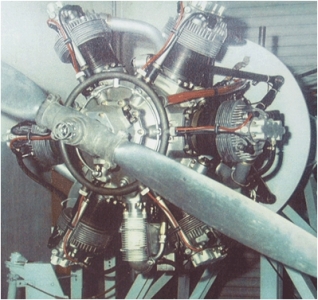

A prototype was built with a max. speed of 1500 r.p.m., excellent for propeller efficiency, the output power is 150 h.p.

The engine has been tested in flight fitted to a Bucker Jungmann 131 small airplane. An important reduction of noise and relevant increase of propeller thrust have been checked by the pilot.

The two images below show the engine on the test bench and fitted to a Bucker Jungmann 131 small airplane.